Chase Performance™ Pty Ltd - Leadership - Employee Engagement - Continuous Improvement

Through our award-winning combination of consulting and services, Chase Performance has created successful business solutions for nearly 15 years. Our successful track record has allowed us to work across a wide range of industries, developing the expertise required to deliver the most premium consulting services available.

Tuesday, October 1, 2013

New Lean Coach

Troy Taylor has recently

joined Chase Performance as a Lean Coach. Educated at Toyota, he has extensive

industry skills in manufacturing, mining and construction. He has authored an

article on Lean Leadership in the current AMT Magazine. You can read it at:

Monday, September 30, 2013

Identifying and deciding your business’ training needs

Implementing training regimes in the workplace can be a

costly and time consuming exercise. At the same time, it is well-documented that

training can improve and increase staff productivity, profits, motivation and

customer satisfaction levels.

Workplace training can take many forms, from in-house one-on-one coaching to mentoring, a push towards self-directed learning or the implementation of external programs to target specific improvement areas.

So how can a business owner identify which training needs

exist in the workplace, and where do they go from there?

The first step – and in some ways, most crucial – step is to

analyse the current skill sets held by employees and identify any operational

performance lapses or gaps.

A thorough audit may undercover communication breakdowns,

missing skills or a lack of overall leadership or direction.Workplace training can take many forms, from in-house one-on-one coaching to mentoring, a push towards self-directed learning or the implementation of external programs to target specific improvement areas.

There is no right or wrong answer, merely a decision of what

is best suited to your goals, employees, budget and time schedule.

If choosing to outsource your training needs, the Federal

Government’s Australian

Skills Quality Authority consumer checklist includes a list of points you

should clarify before committing to an opportunity.

Key points include confirming that the organisation is a

registered training provider, ascertaining which industry bodies or

associations they are affiliated with and ensuring that the key outcomes are

relevant to your goals and expectations.

Both State and Federal Governments offer significant

incentives for organisations that implement training regimes.

Ultimately, the decision comes down to a needs and benefits

basis- what is your workplace lacking and how can a structured training

solution assist you improve in the area?

The basic principles of Lean Leadership

Lean Leadership is a prominent phrase throughout the

corporate sector– but what exactly does it encompass?

In its original definition, Lean refers to a form of

continual improvement, with the term coined by motor giant Toyota. Whereas the

expression was once mutually exclusive with the manufacturing industry, these

days it is applicable to a range of industries including professional services,

healthcare and accounting.

Lean Leadership, in its basic form, aims to push people out

of their comfort zones and face constant innovation and new processes.

When implemented successfully, it reduces waste and

ineffective time usage, resulting in increased overall company performances and

bottom line.

Some of the key attributes possessed by Lean Leaders include:

· Defining success – Lean Leadership has an emphasis

on a positive work-life balance. While many managers, executives and CEOs have

professional objectives and goals, truly strong leaders also have personal

mission statements and targets away from the office.

· Understanding yourself – Many people have inaccurate

perceptions of their own skills and abilities, regardless of whether they are

overestimating or underestimating their capabilities. Lead Leadership focuses

on 360 degree feedback to improve a leader’s understanding of their strengths

and weaknesses.

· Knowing when to follow – A strong leader inspires other

people to follow them. But it is not always necessary to lead – the best

leaders of all can identify when to take a backseat and allow somebody else to

take ownership of a project or task. Empowering others allows them, in turn, to

improve their own leadership skills.

· Ability to challenge the status quo – The desire for continuous

improvement and the quest for perfection are Lean Leadership priorities. To

achieve these goals, some leaders may on occasion need to challenge popular or

prevalent perceptions within the workplace.

Most Lean Leadership programs will commence with a Lean

Maturity Audit, assessing your workplace and each department against world’s

best practice to identify operational performance gaps.

Wednesday, September 25, 2013

Footy Tipping Winners

Congratulations to the winners of the Chase

Performance Footy Tipping Competition:

- 1st Prize (iPad Mini) went to Paul

Judge alias 'Snorin'Norman'

- 14th Prize($250 Coles/ Myer Voucher)

went to Chloe Buhuslav alias 'headstrong'

- Last Prize (Wooden Spoon) went to

Belinda Papa

Chase Performance has a new website

We are pleased to announce the release of our new

website, designed with a fresh new look and user-friendly navigation,

updated with the latest information about our consulting services.

You will be able to watch the latest video

testimonials and read the most updated news and case studies.

One of our main goals was to build a user-friendly and simple to

navigate site. The new design allows the users to quickly find the contents

thanks to its low hierarchical structure.

Monday, July 29, 2013

What is 5S?

5S is a basic, fundamental, systematic approach to quality, productivity and safety improvement.

It is relevant to all businesses and focuses on:

The benefits of 5S are:- Improved visual communication

- Improved safety

- Improved productivity

- Improved morale

- Improved use of space

- Reduced inventory and supply costs

- Showcasing your work area

- A higher quality of customer service

- Profitability

- Efficiency

- Service

- Safety

Contact us on 1300 880 338 to talk to one of our Business Improvement Consultants on creating meaningful change in your organisation.

Sunday, July 28, 2013

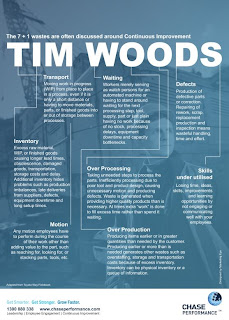

TIMWOODS - 7 + 1 Wastes (Taken from Toyota Way Fieldbook)

Here is some more information in regards to the seven plus one wastes often discussed around Lean Six Sigma.

- Transportation or conveyance Moving work in process (WIP) from place to place in a process, even if it is only a short distance. Or having to move materials, parts, or finished goods into or out of storage or between processes.

- Inventory Excess raw material, WIP, or finished goods causing longer lead times, obsolescence, damaged goods, transportation and storage costs, and delay. Also, extra inventory hides problems such as production imbalances, late deliveries from suppliers, defects, equipment downtime, and long setup times.

- Movement Any motion employees have to perform during the course of their work other than adding value to the part, such as reaching for, looking for, or stacking parts, tools, etc. Also, walking is waste.

- Waiting (time on hand) Workers merely serving as watch persons for an automated machine, or having to stand around waiting for the next processing step, tool, supply, part, etc., or just plain having no work because of no stock, lot processing delays, equipment downtime, and capacity bottlenecks.

- Overproduction Producing items earlier or in greater quantities than needed by the customer. Producing earlier or more than is needed generates other wastes, such as over-staffing, storage, and transportation costs because of excess inventory. Inventory can be physical inventory or a queue of information.

- Over processing or incorrect processing Taking unneeded steps to process the parts. Inefficiently processing due to poor tool and product design, causing unnecessary motion and producing defects. Waste is generated when providing higher quality products than is necessary. At times extra “work” is done to fill excess time rather than spend it waiting.

- Defects Production of defective parts or correction. Repairing of rework, scrap, replacement production, and inspection means wasteful handling, time, and effort.

- Skills under utilised Losing time, ideas, skills, improvements, and learning opportunities by not engaging or listening to your employees.

Subscribe to:

Comments (Atom)